With more sensors in compressors and availability of advanced remote monitoring capabilities, fast and accurate analysis and troubleshooting of problems are enabled. Theoretically, this should lead to a decrease in compressor maintenance and service cost. Why isn’t condition-based maintenance still an industry standard for air compressors?

Compressor business today – where is the money?

The traditional air compressor business (for the suppliers, manufacturers and sales channels) has relied on two main pillars – equipment sales and service sales. The profitability of air compressor sales, perhaps apart from the few top compressor manufacturers, has been on the decline with commoditization of compressor technologies. Apart from “oil-free” compressors, the independent distributors are often forced to often drop average sales margins to the single digits in equipment sales.

The largest compressor company profit generator has been and still is, the sales of consumable, maintenance and service parts and labor for keeping the compressed air equipment operational. This business model is very common in other industrial goods businesses as well. Customers, the users of the equipment, have been grinding their teeth and have kept paying the high-cost of maintenance and service because they have really had no options – the air compressor must be kept working, regardless of the cost.

A typical time-based maintenance program for oil-free air compressors may look like this:

- oil filter change every 1,000 hrs,

- air filter change every 2,000 hrs,

- oil change every 4,000 to 8,000 hours,

- service of valve seal kits every 24 months,

- motor re-bearing work every 5 years,

- “oil-free”, screw air end changeout every 40,000 hours

The increased sensor-based monitoring capabilities with the breath and volume of information available in modern compressors, make it easy to change the service and maintenance from Reactive (“something breaks -> we’ll fix it”) to Preventive (“we’ll fix it before it usually breaks”) to Predictive (https://en.wikipedia.org/wiki/Predictive_maintenance) and to Condition-Based Maintenance (CBM) (“we’ll fix it just before it actually breaks”). Unlike planned maintenance, where maintenance is performed based upon predefined scheduled intervals, condition-based maintenance is performed only after degradation in the condition of the compressed air equipment has been observed. Compared to Preventive maintenance, CBM increases the time between maintenance repairs, because maintenance is done on a need-based model in which the information enables decision-making.

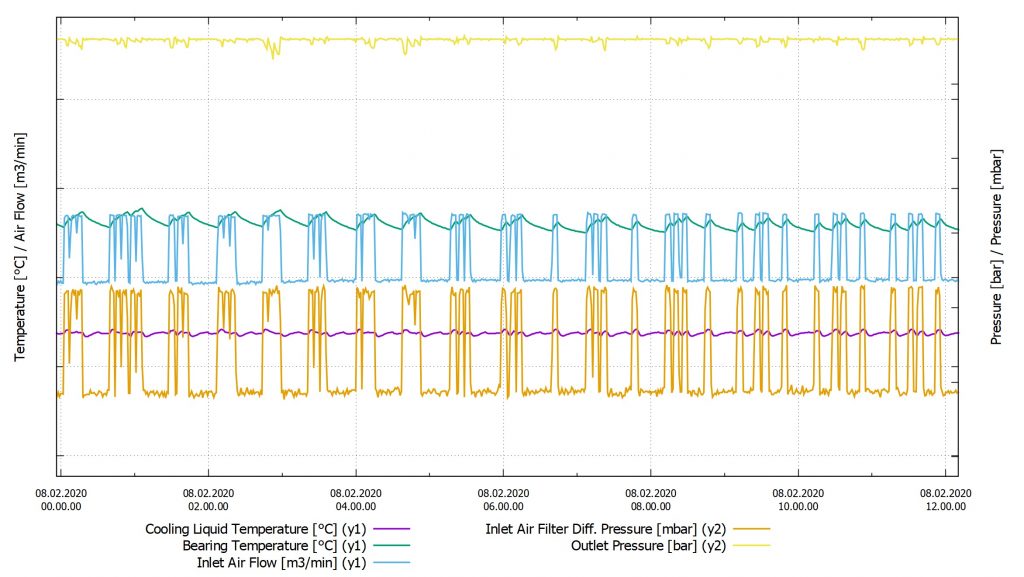

Condition-based maintenance (CBM) is a maintenance strategy that monitors the actual condition of air compressor or whole compressed air installation to decide what needs to be done and which part of the installation needs to be addressed. CBM dictates that maintenance should only be performed when certain indicators show signs of decreasing performance or upcoming failure. Condition data can then be gathered at certain intervals, or continuously (when a machine equipped with different kind pre-installed sensors). For example, the data indicates when intake air filters are reaching end-of-life (from the pressure drop measurement by pressure sensors) and replacement can be done when really needed. With proper design, air filter changes have been pushed up to 25,000+ hours without excessive pressure differential or loss of filtration. This technical capability is already available in most high-end air compressors, but not utilized or utilized mostly for manufacturer own internal use: R&Ds and product improvement programs.

The motive for not utilizing the available data and connectivity is clear: customers have been trained over years of current practice to buying these services on a reactive or time-based model. Some are suspicious of preventive maintenance which may seem even a bit of a hoax with all the disclaimers and exclusions.

When is condition-based maintenance used on compressed air equipment?

In general, equipment or whole installation must meet certain requirements for CBM to be used effectively.

First, there must be conditions that can be monitored. If performance of compressed air installation or its components cannot be measured, you won’t be able to tell if there is a change in performance of any components inside of air compressor, which indicates the need for maintenance.

It is also crucial to be able to observe these changes in the compressor’s performance far enough in advance of failure so maintenance can be completed before the machine fails or deterioration affects operations or compressed air quality. Remotely gathered compressed air system data can be used to understand the installation characteristics and to suggest improvements.

Though, compressors are usually not the most technologically advanced equipment – compressed air quality and availability are critical for any industrial production. From this perspective, the condition-based maintenance provides the best return on investment and lowest total cost of ownership. That’s why it’s a great idea to conduct analysis to determine which component(s) are the most likely to fail, impacting the quality of compressed air and operational security of air compressors, dryers, filtration or other components.

Lastly, condition-based maintenance can only be used if the right systems and processes are in place for monitoring. Maintenance or technical support teams must be able to capture performance data, analyze it, and make timely decisions based on the results. CBM systems should be powered by machine learning and AI components on the manufacturer side and should provide to customer comprehensive, factual information with suggested preventive actions.

Condition-based maintenance – Pros and Contras

Benefits

What are the benefits of condition-based maintenance for compressed air installations? There are many advantages to using condition-based maintenance on assets, especially in a production-intensive equipment-heavy environment. Here are a few of the major benefits that can be gained from CBM:

- It is much easier to predict failure and fix it before it occurs, which means CBM will help reduce unplanned downtime and labor hours while increasing throughput.

- The time between maintenance increases because repairs are only done on an as-needed basis. This means less downtime, reduced backlog, and fewer operational costs on compressed air installation.

- The likelihood of disrupting production is reduced as CBM is on-going while machines are working and don’t normally require equipment to shut down for inspection as it is known already from the performance monitoring data.

- Using CBM can lead to quicker diagnosis of the problem, thereby reducing the cost of breakdowns.

- Because CBM provides an early warning system for equipment failure, the control of critical elements within compressed air equipment or whole installation is much more effective. Users won’t need as many emergency spare parts to order or to wait for delivery.

- Condition-based maintenance improves worker safety by reducing the likelihood of equipment failure.

- CBM helps prescribe the optimal amount of maintenance for an air compressor, dryers or air filters; decreasing the chances of collateral damage to its systems.

- Minimizes unscheduled downtime due to catastrophic failure

- Minimizes requirement for emergency spare parts

- Minimizes time spent on maintenance and overtime costs by scheduling the activities

- Optimizes maintenance intervals (more optimal than compressor manufacturer recommendations)

Downsides

- Condition monitoring test equipment is expensive to install, and databases cost money to analyze.

- It is a costly and long-term process: staff training and development – users need knowledgeable professionals for data analysis and perform the work.

- Some sensors may not survive in difficult operating environments – let’s take extremes: “oil-free” compressors with adsorption dryer and filtration systems installed in a hospital and an air compressor installed in a container for operation in the oil field in the middle of a sand desert.

- May require modifications of previous generation compressors and retrofitting the machines and components with sensors.

- With CBM in place, it still requires competence to turn performance information from a system into actionable proactive maintenance items.

- CBM could increase the unpredictability of maintenance periods.

Why condition-based maintenance is still not an industry standard for air compressors?

Theoretically, advancements in technology with more sensors in compressors and remote monitoring capabilities for analyzing and troubleshooting problems should lead to a decrease in compressor maintenance and service cost. This does not often materialize, as new capabilities are not used to their fullest extent.

However, as suggested above, the business model for most compressor companies relies substantially on steady high aftermarket revenue from maintenance and service on most common industrial compressors. Oil or water -injected or “oil-free” screw compressors generate somewhere close to 50% of total business revenue. Thus, – why cut the branch you’re sitting on, right?

Used sources:

Condition-based maintenance (CBM) https://www.fiixsoftware.com/condition-based-maintenance/

Remote Monitoring Paradigm Shift in Air Compressor Maintenance https://www.tamturbo.com/remote-monitoring-paradigm-shift-in-air-compressor-maintenance/