Global consumption of paper and paperboard has reached over 420 million tons per year, with China and the USA consuming almost half of all paper-based products manufactured worldwide. The trend in paper industry is turning from traditional paper to more sophisticated products like demanding packaging solutions and specialty papers. To keep up with demand, pulp and paper manufacturing plants require a continuous flow of oil-free compressed air to supply the near-constant production rate.

As paper and board products are used across almost all industries for packaging, labels, and more, manufacturers need to maintain the highest standards to ensure consumers’ safety. This sets strict quality requirements for compressed air systems as well. Learn more about how compressed air is used in the paper industry and how oil-free air compressors help plants comply with safety guidelines and create more efficient production practices.

Compressed Air Applications in the Paper Industry

Oil-free compressed air is essential for almost every part of the paper manufacturing process.

Compressed air is used throughout the entire paper manufacturing process from separating and cleaning the raw pulp fiber to final product. Oil-free compressed air is a mandatory utility in every step as process and instrument air.

Safety and Quality Requirements

Clean, oil-free air ensures smoother operation and guarantees that all manufacturing practices and paper products meet strict safety and quality requirements.

The International Organization for Standardization recently released guidelines for air purity in the manufacturing sector. The ISO 8573-1 (2010) ruling states that air compressors marketed as oil-free and used for manufacturing must have no oil emissions to receive Class Zero status.

In the United States, the Environmental Protection Agency (EPA) regulates pollutants in the pulp and paper industry. This ensures that all paper products manufactured by plants do not contain oil or other contaminants that could damage people or the environment.

The FDA also plays a role in quality control, as many paper products are used in the packaging for food, beverages, and pharmaceuticals. According to the Code of Federal Regulations (CFR) Title 21, packaging may not contain any substances deemed harmful for human consumption, including the oil used for powering and lubricating air compressor parts.

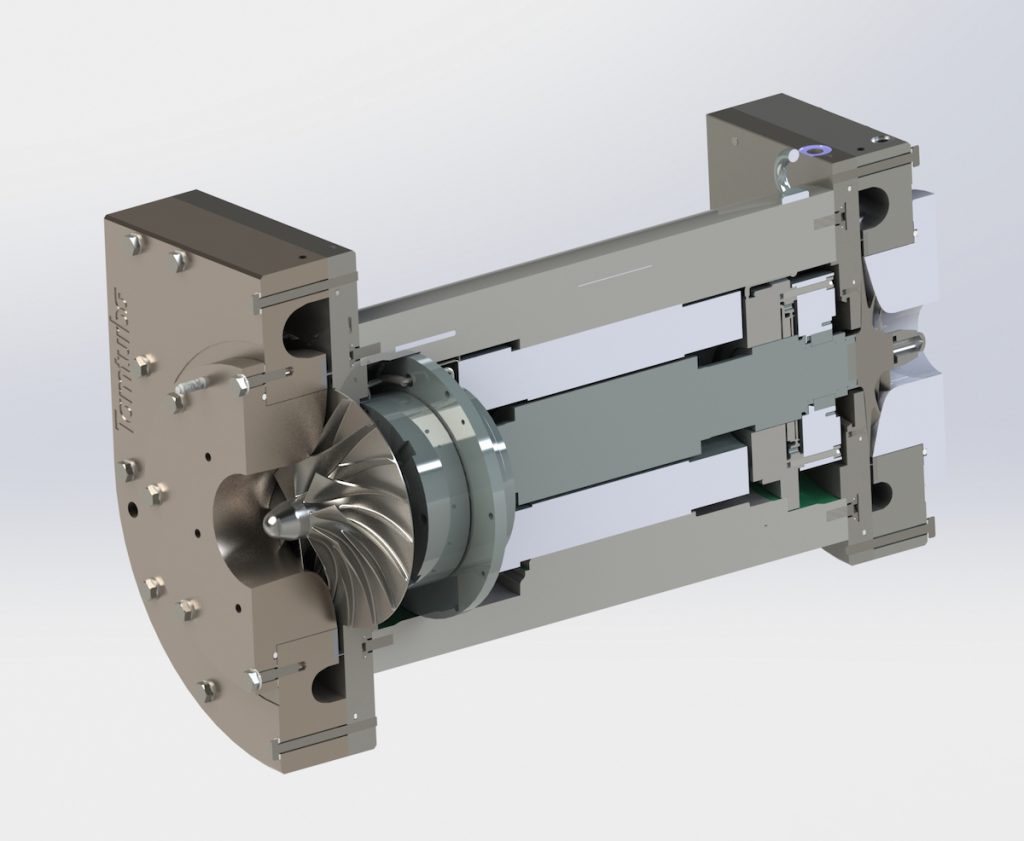

Unfortunately, many dry rotary screw air compressors marketed as oil-free still require oil for lubrication, which can work its way into the air stream. Contrary to traditional “oil-free” technologies, Tamturbo® Touch-Free™ VSD Air Compressors are genuinely 100% oil-free.

Tamturbo Air Compressors use Active Magnetic Bearing (AMB) technology, which allows the compressor parts to move without touching, eliminating the need for oil and mechanical wear and tear. With no oil and no oil filters to dispose of, Tamturbo VSD Air Compressors help your paper plant comply with safety and quality regulations.

Precision Air Pressure Control with VSD Compressors

For an industry such as pulp and paper manufacturing that requires 24/7 continuous operation, air pressure control is critical for an efficient and cost-effective plant.

Variable speed drive (VSD) air compressors are designed to keep the network pressure stabilized within tight parameters in the compressor’s designated variable speed range. Tamturbo’s compressors use a 3-stage core that is remotely monitored and controlled to ensure reliability and consistency in the paper manufacturing process.

Efficient Manufacturing Processes with Compressed Air

With such a huge demand for paper products worldwide, manufacturing plants must operate efficiently to minimize time and resource wastage. Interruptions to production schedule due to maintenance or breakdowns are expensive, so paper plants need air compressors that reliably deliver clean compressed air with minimal maintenance.

The efficiency of your company is Tamturbo’s priority. An efficient plant is a productive plant, and Tamturbo’s maintenance-free VSD air compressors keep your plant operating optimally. Tamturbo air compressors are optimized for a wide output capacity range. This enables the units to work more efficiently at low range when less power is required and avoids costly spikes in energy consumption.

Tamturbo’s gearless drive units use titanium turbo impellers that do not touch and will not wear due to friction, effectively eliminating maintenance needs. Additionally, the compressor core with no wear means exceptional efficiency that sustains. For more sophisticated optimization of your compressed air production, Tamturbo units are remotely controlled.

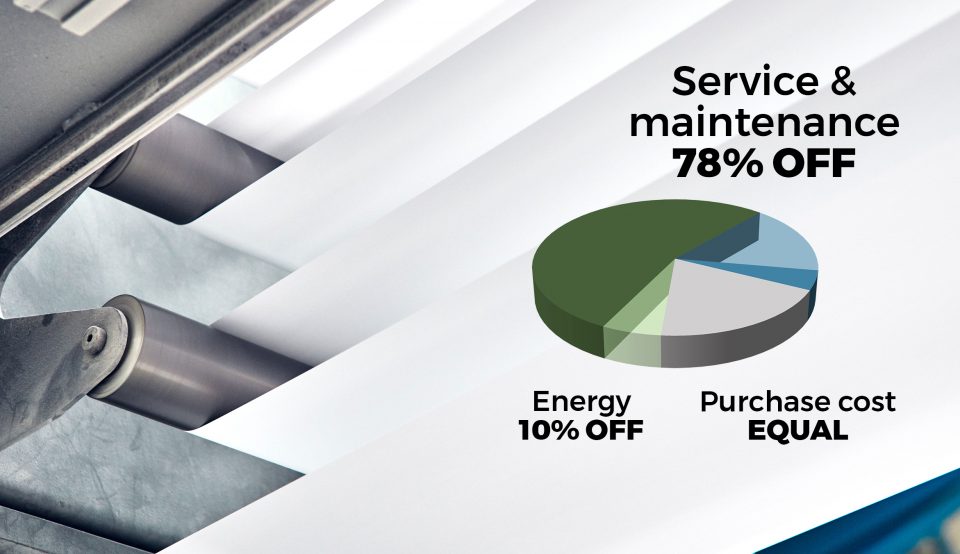

Sourcing Cost-Effective Compressed Air

Compressed air accounts for up to 10% of all energy consumption in the manufacturing industry. As the paper industry uses compressed air constantly, compressors can quickly eat into the company’s profits.

In traditional technologies like “oil-free” screw, friction between moving parts causes units to become inefficient, requiring more power to work. Magnetic levitation, as used in Tamturbo Touch-Free™ Compressors, eliminates wear and tear due to friction and reduces the need for downtime due to maintenance for more cost-effective compressed air.

Another way to reduce compressed air costs is the Tamturbo Touch-Free™ Air service contract. Touch-Free™ Air allows you to benefit from the energy-saving from VSD and magnetic technology while reducing the overall cost of ownership; all you pay for is the air you use.

Creating an Eco-Friendly Paper Manufacturing Industry

While the paper manufacturing industry has made significant progress towards more eco-friendly practices by utilizing recycled products and minimizing emissions, energy consumption is still a major contributor to a paper company’s overall carbon footprint. Energy-efficient air compressors help to mitigate the cost of powering the equipment in a manufacturing plant.

Tamturbo air compressors use a standard liquid cooling system that allows the unit to recapture up to 93% of the compressor power to be used for heating, drying, or driving other equipment.

By using magnetic levitation technology, Tamturbo air compressors can operate completely oil-free. This means cleaner wastewater, and no messy oil-filter disposal required.

The VSD motor offers increased energy savings as it can control the unit’s speed depending on the plant’s compressed air needs, so the compressor does not need to operate at full capacity all the time.

Choose Tamturbo Touch-Free™ Air Compressors for Cleaner Compressed Air

Pulp and paper manufacturing plants require clean, continuous, reliable compressed air to power almost every piece of processing equipment. Tamturbo uses state-of-the-art technology to create energy-efficient units that require minimal maintenance, so you won’t experience costly downtime.

If you are searching for a reliable source of oil-free compressed air for your company, contact Tamturbo to discuss which of our units is right for your facility.