Why go for the low hanging fruit still in the tree when you have basket full of unused fruits?

At the start of the new year everyone is planning the most impacting and important projects to fulfil this year’s goals and targets. For people responsible for sustainability, this work has most likely started during the budgeting cycle last year already. But the practical work starts now.

Finding impactful sustainability projects is not difficult in most cases since there are plenty of possible initiatives to take forward. However, most of them require collaboration with production and plant people, who are often preoccupied with the daily firefighting and aspects related to the core function of the company. Hence, instead of starting a project to do something that would not be done otherwise (like replacing lights with more efficient ones or installing solar panels to reduce the amount of purchased electricity) it’s often easier to influence the selection of the assets that will be replaced anyway, to reduce the consumption of energy. This is when compressors, which on average consume 10% of industrial electricity, come to the picture.

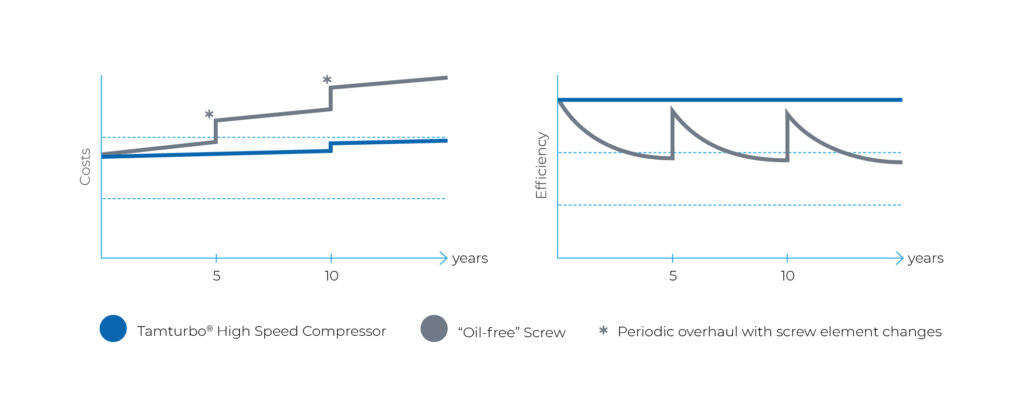

What makes them good candidates for this free lunch is that traditional “screw” type oil-free compressors are overhauled every 4 to 7 years, with the cost of 60 to even 80% of the new compressor. At this point it is worth noting that the energy efficiency of the compressor in question unfortunately never reaches that of a new one, but that’s another story. After overhauling, a traditional oil-free “screw” type oil-free compressor can function another 4 to 7 years. Meaning that if your plant has 5 compressors it is likely that almost every year you are spending that money to keep the assets running at all, and still consuming on average 10% of your electricity.

With roughly the same amount of money, and with less effort and no risk, you can take a leap in your sustainability targets by choosing a compressor that

- uses 10 to 20% less electricity

- requires no overhauls (ever!) and

- Is able to return most of the used energy as high temperature heat.

This means that with the same effort you get triple benefits: monetary, electricity and primary energy reductions. And, as a bonus, you don’t need to convince your colleagues to do anything additional, you can help them do their core job better and improve your company’s sustainability KPI’s at the same time – get tangible impact on your time spent.

So, in this case taking the easy road is, well… easy. Convincing your colleague to do something that they anyway will do but doing it slightly differently is far easier than convincing them to do something outside their core responsibilities. Eating the existing fruit salad is much more fun than scavenging for the fruits hanging in the different trees! Contact us to learn more.