When discussing technologies, the phrase “good old times” isn’t always true. 60 to 100+ year old screw compressor technologies use oil in one form or another, opening the possibility of oil or other harmful components ending in what we eat or drink. Even “oil-free” screw compressors use tens of liters of oil to lubricate the gear box and bearings.

From bakeries to dairies and from meat packing to beverage bottling, compressed air is widely used in the production process. It is not widely known that so called “oil free” compressors actually contain oil for lubrication of bearings and gears. This oil can get into the air stream either by leaks through oil seals or from indigested oil vapors from the compressor’s oil lubricated gear box. Air compressor lubrication oil in food or beverage products is absolutely unacceptable and can have catastrophic consequences. The risk of hydrocarbon contamination of edible products is just not worth taking. Nevertheless, many production plants use compressors that need oil to function.

In addition to the risk of contaminating the air, old “oil-free” technology comes with high maintenance costs. In “oil-free” screw compressors, the air is compressed through the screw units. During the years, the screw elements wear and the efficiency of the compressors quickly deteriorates and costly overhaul is required. Despite their names, “oil-free” compressors use tens of liters oil to lubricate gears and bearings. Oil needs to be changed regularly and oil and oily waste must be disposed of properly. In addition to all these costs, there are filtering costs. The screw technologies have to use filters which increases the total cost of ownership when the maintenance costs of the compressor are high to begin with. Tamturbo Touch-Free™ compressor does not add anything to the compressed air, not oil or coatings like Teflon.

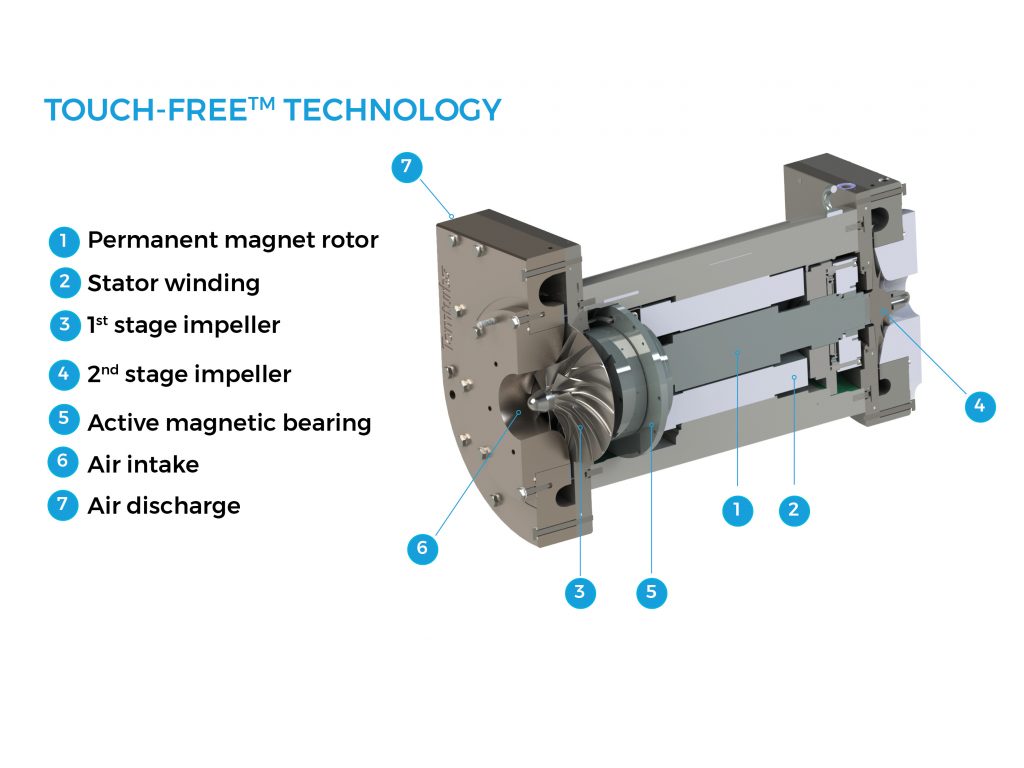

Tamturbo® compressors are 100% oil-free thanks to their unique technology with active magnetic bearings that keep the motor shaft magnetically levitating at all times. This means there are no gears or bearings to lubricate, no oil filters or oily waste to worry about, or no mechanical seals or any other parts that touch or wear. Without oil in the system, the compressors are completely risk-free from oil adding any contamination in compressed air. With our 21st century compressor technology, you can be Care-Free knowing that we have your compressed air production secured.