Paulig is an international food and beverage company located in 13 countries and offering products in more than 70 countries. . Paulig is the market leader for coffee in Finland and in the Baltic countries and for Tex Mex in Europe. Building a successful business means responsible choices, decisions and actions every day.

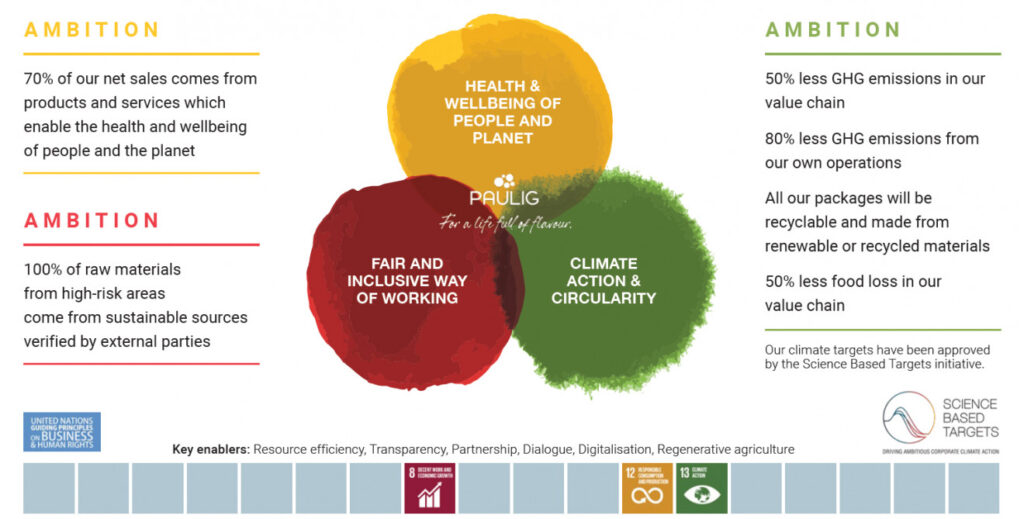

Paulig is a sustainability frontrunner in the food and beverage industry. Part of the Paulig Sustainability Approach 2030 is the company’s science-based climate targets, which are approved by the Science Based Targets initiative. Paulig aims to reduce its greenhouse gas emissions from its own operations by 80% and by 50% from its value chain by 2030.The collaboration with Tamturbo is one step towards the aim to reduce emissions in its own operations at the Vuosaari roastery in Helsinki.

The compressed air requirements of Paulig and the food and beverage industry in general

As for the rest of the food and beverage industry, Paulig has very strict demands for their compressed air production. High efficiency, oil-free compressed air and superior reliability are the most important requirements when looking at their compressed air system. As their old air compressor system was at end of its life-cycle at the coffee roastery in Vuosaari and requiring excessive maintenance and overhaul, Paulig was interested in the uniqueness of Tamturbo compressor technology and the benefits of a 100% oil-free high speed magnetic bearing turbo compressor and a service solution that allows them to concentrate in their core production. In order to fulfill these strict requirements, Tamturbo offered Paulig 100% oil-free high speed turbo compressors with Tamturbo® Touch-Free™ service model for outstanding reliability and efficiency to maximize potential for their new compressed air system.

Towards a sustainable and reliable compressed air system

The compressed air system at Paulig contains two TT185 high speed turbo compressors that use the latest active magnetic bearing technology to enable rotor shafts levitate in air to prevent any mechanical contact, thus removing any need for oil lubrication systems and annual oil changes that typical “oil-free” compressors have. The compressors are paired with adsorption dryers to guarantee a low dewpoint requirement. Compressed air is then used for different manufacturing processes such as packing and nitrogen generation. The compressors automatically adjust rotational speeds with VFD control to match plant air demand without typical network pressure fluctuations. The compressor system was equipped with Tamturbo PLS™ (parallel load sharing) option, which balances running hours between two of the compressors allowing them also to work as a united variable load system in case for peak compressed air consumption situations.

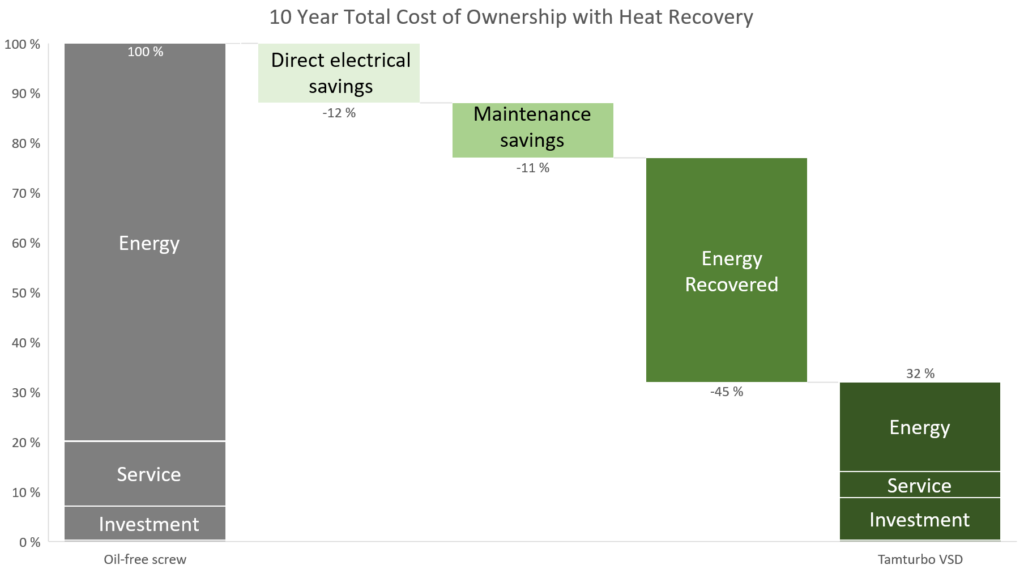

Reducing plant district heating use up to 45% with compressor heat recovery and heat pump

With the on-going energy crisis and increasing demand for sustainable production, companies must constantly seek new technologies to save energy. Compressed air production is a very energy intensive process, however, Tamturbo compressors are able to recover up to 93% of the energy used for compression. Understanding this, Paulig decided to combine this feature with their liquid cooling system and utilize the recovered heat for factory heating system with the help of a heat pump. By utilizing the heat from Tamturbo compressors, Paulig is able to reduce use of district heating as much as 45%, which translates into maximized efficiency, sustainability and significant cost savings or, in other words, enabling compressed air production almost for “free”. Combined benefits from Tamturbo solution, reduced maintenance needs and heat recovery feature enable a unique improvement compared to the previous compressed air system.

“Tamturbo compressors enable us to improve our plant sustainability and air quality efforts by offering a total service solution for compressed air production. Tamturbo service allows us to focus on our core production as a food and beverage manufacturer. “

Nikolai Raita, Paulig

Read more about Paulig’s sustainability work

Read more about Paulig’s heat recovery (Finnish)

Read more about Tamturbo heat recovery

Contact Tamturbo for more information:

Timo Sihvo, Sales Manager Nordics

timo.sihvo@tamturbo.com

tel. +358 40 820 8522