Tamturbo® Oil-Free Compressors are perfect for every industry that requires oil-free compressed air, with zero tolerance for oil contamination. The food-and-beverage, pulp-and-paper, pharmaceutical, biotech, electronics, textile and medical-device industries are all typical users of our energy-saving compressor technology.

You too can benefit from using Tamturbo® Oil-Free Air Compressors for your business. How? Read on and find out!

Higher Profitability with up to 15% Lower Energy Costs

You may not be able to control how much your electricity provider charges per kWh of electricity. But, you can control how many kWh they bill you for.

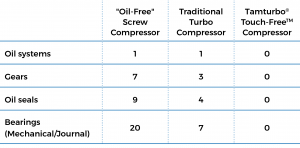

When an old-fashioned compressor’s moving parts start to operate, the resulting friction results in wear that causes a loss of energy. Air pressure is also lost through filtration. Obsolete “oil-free” screw-and-centrifugal compressors rely on multiple energy-robbing gears and bearings with metal-on-metal contact, oil seals and oil filters. Due to their complexity, they require a lot of maintenance, and the efficiency of “oil-free” screw compressors quickly deteriorates. This typically increases energy consumption as much as 10-15%. It also results in frequent overhauls. All of it is very expensive.

Tamturbo® Variable Speed Drive (VSD) technology controls the motor speed based on actual air demand to maintain constant air pressure. Floating above magnets, the motors rotate at speeds of over 35,000 RPM for optimal efficiency.

The VSD and a sophisticated control system make possible the industry-leading-capacity-turndown range of up to 63%, ensuring your compressor matches your air needs precisely.

Freedom from energy wasting blow-outs also means energy savings for you. Tamturbo® Oil-Free Compressors minimize the energy wasting blow-outs, unlike the last-century-style compressors. When you need air, you got it. When you do not, none is wasted.

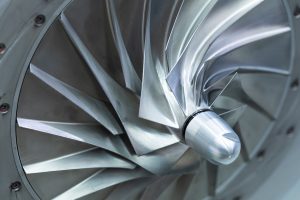

Tamturbo® gearless drive units are unique. The titanium turbo impellers never wear out and the lack of friction and no metal-on-metal contact ensures consistent efficiency. With the ability to adapt to fluctuating air requirements within your facility, the efficiency remains constant over time. No costly spikes in energy consumption, typical with the old compressors.

Tamturbo® Oil-Free Compressor efficiency stays constant during its entire lifecycle.

Your energy savings stay constant as well.

Higher Profitability with Virtually Zero Maintenance Costs

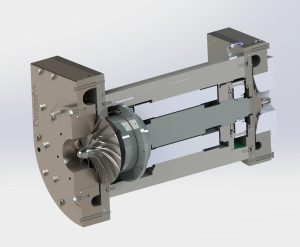

The ingenious design of Tamturbo® Oil-Free Compressors eliminates nearly everything that often goes wrong with old-style air compressors: the gears, bearings, seals, oil separators, oil pumps, filters and of course, oil. The design is based on high-speed motors floating on Active Magnetic Bearings (AMB). Titanium impellers produce the air. The core unit is completely maintenance free.

Whether planned or unexpected, compressor downtime adds unnecessary expenses to your business. Unlike typical hourly maintenance, your Tamturbo® Oil-Free Compressor is serviced only when needed, based on real-life data. The service needs are detected and planned for well in advance. Tamturbo® Oil-Free Compressors are being monitored 24/7 from a remote operation center.

Most issues that come up are resolved remotely. Intake air filters need to be changed from time to time, as do some O-rings, but our maintenance engineers at Tamturbo® will inform you of the very few maintenance procedures long before they become urgent. And, if you choose our Touch-Free™ Air program or Care-Free maintenance plan, we will take care of that too.

Recover the Energy

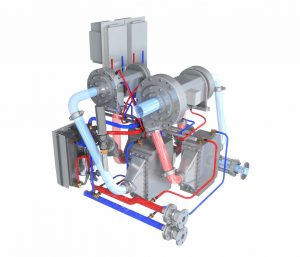

Tamturbo® compressors offer significant energy savings by recovering the energy used to generate compressed air.

Most compressors waste this energy by blowing it out into the atmosphere. Not Tamturbo®! Our liquid cooling system converts up to 93% of the energy used to generate compressed air, to plain hot water. You can then utilize the energy again for your industrial processes, heating system, service water or other needs. And because the compressor is 100% oil-free, there is no risk of contaminating your energy-recovery system with oil.

The variety of easy heat-recovery options with Tamturbo® compressors separate them from the competition. With the optional Boosted Heat Recovery (BHR), the temperature of returning water can be raised all the way up to 90°C.

It saves you money. And, when you combine the 93% energy recovery with up to 15% direct energy savings, you also reduce the carbon footprint of your operations significantly. Better for your bottom line. Better for the planet. Better for you.

Zero Environmental Impact from Oil-Based Waste

Tamturbo® Oil-Free Compressor contains no oil. It has no oil filters. Neither need changing because they do not exist! Thus, there is zero impact on the environment from oil-based waste.

Reliability

Reliability is what you get with a Tamturbo® Oil-Free Compressor. Instead of Teflon or oil for lubrication, Tamturbo® Touch-Free™ compressors use Active Magnetic Bearings (AMB). The moving parts do not come into contact with anything while in operation, except air, of course.

Thus, there is no gearbox to repair. No components to replace. Most maintenance procedures are handled remotely by our maintenance engineers via computers from Tampere, Finland. Only if needed.

The result? Uninterrupted production for your business.

Longer Compressor Life Cycles

By providing friction-free rotation with zero drag and no metal-on-metal contact, the components will not ever wear out or break down. The Active Magnetic Bearings react instantly upon starting the compressor, eliminating vibration completely.

Self-protecting magnetic levitation also prevents damage in the event of a power outage, as power stored in the rotation and in the capacitors keeps the bearings energized until the motor slows down and stops.

Tamturbo® Oil-Free Compressors do not lose efficiency due to wear as there is no metal-on-metal contact between rotating components.

The advantage to you? Much longer life cycles from your compressors.

Stop wasting money on old-fashioned compressors! Bring your compressors to the digital age. With up to 15% in energy savings. Guaranteed.

For more information on our compressor solutions for your business, contact us for a no-commitment consultation today.

Just like our compressors, if it’s more convenient for you, we will manage the consultation remotely.