Touch-Free

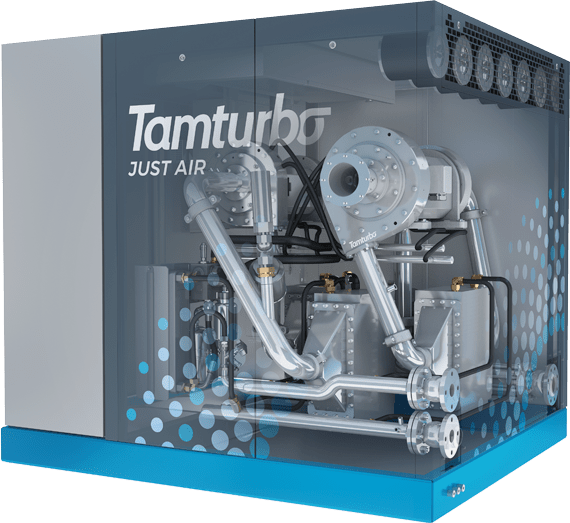

Parts that don’t touch, don’t wear. All Tamturbo® Touch-Free™ Technology air compressors are direct driven high-speed VSD centrifugal compressors that produce 100% oil-free compressed air for industrial customers.

Read moreOil-Free

We have absolutely no oil in our compressor. Tamturbo® Touch-Free™ compressors have impellers mounted on the high-speed motor shaft while producing 100% oil-free compressed air.

Read moreCare-Free

Maintenance-free Tamturbo® Technology makes compressed air care free. All Tamturbo® Touch-Free™ Technology compressors are direct driven high-speed VSD turbo compressors that produce 100% oil-free compressed air for industrial customers.

Read more