Is product quality important to you?

How about avoiding contaminating your product or production process?

Do you value zero risk of oil contamination in your compressed air?

If the answer is yes, please continue reading.

Feel like paying for air compressor oil service, along with oil filters, oil separator elements and recycling of the waste?

Is it ok to drain oily condensate water into the sewer system?

The answer is obviously no and the solution is simple.

You need an oil-free air compressor! But did you know that not all oil-free air compressors are free of oil?

No oil changes, ever!

Did you know that many so called “oil-free” compressors need a lot of oil to lubricate gears and mechanical bearings? For example, a 250kW (340hp) “oil-free” screw compressor contains approximately 70l (15 gal) of oil. Air purity is critical in many applications, and if your process is exposed to oil, it’s both difficult and expensive to clean the compressed air system and potentially reject contaminated products.

All oil-lubricated compressors but also many “oil-free” compressors need oil to lubricate mechanical contacts in the gear box. In the oil-lubricated compressors, also screw elements, where the air is compressed, are lubricated with oil to reduce friction and wear, to absorb the heat of compression and to seal the air compressor.

Even if oil is almost a perfect lubricant, it needs to be changed regularly to preserve the lubrication properties. In addition to this, the oil filters need to be changed. Used oil and oily waste need to be handled properly. Due to wear, the air compressor efficiency decreases and the screw elements need to be refurbished or replaced. Compressor service is always expensive and the compressor is inoperable during the maintenance.

Tamturbo® Touch-Free™ technology is 100% oil-free – the turbo compressor does not contain any oil. The technology is based on permanent magnetic motor and active magnetic bearings (AMB). Thanks to the AMBs, the rotor and turbo impellers of the compressor levitate in air and do not come into contact with anything. With no metal to metal contact, the compressor does not wear or need any lubrication. Tamturbo turbo compressors are directly driven variable speed drive (VSD) compressors without gear box or couplings. VSDs are used to change the motor speed to match the compressor output to air demand.

Are you interested in eliminating risk of oil leaks?

Traditional “oil-free” compressors use oil as lubrication much the same way that oil-lubricated compressors do. If you have visited a compressor room, you know that most compressors leak oil. That’s why it’s handy to use a sorbent material under the oily compressors to ease the cleaning. This is not a problem with Tamturbo® 100% Oil-Free turbo compressors. There’s not a drop of oil in the entire compressor and we can guarantee that there are no oil leaks or cleaning, or oily condensate water to clean, ever. With Tamturbo® turbo compressors, your compressor room is as nice and clean as your compressed air. You can forget the oily sorbents and oil puddles.

Don’t smudge yourself with oily condensate water

Atmospheric air contains always moisture. When air is compressed, the same volume contains more air and moisture, causing the moisture to condense into water during compression. All air compressors produce large amounts of condensation water each and every day.

If oil-lubricated compressors are used, some of the compressor oil ends up in the compressed air and condense water. How to deal with oily condensation water? It is typically illegal to discharge the oily water into the sewage system and the oily condensation water increases the daily waste treatment quite a bit.

With Tamturbo® 100% oil-free compressor, condensation water is free of any oil and can be discharged into a drain. You don’t have to worry about costly waste treatment. You can just produce compressed air and feel Care-Free.

Save money and the nature

In contemporary business life, we often have to make difficult decisions whether we save money or nature. In tough international competition, savings are essential. At the same time, customers want to have more responsible and climate friendly products. Sustainability has added value in the market. What if you don’t have to choose between savings and nature? With Tamturbo® Touch-Free™ turbo compressors you can have both.

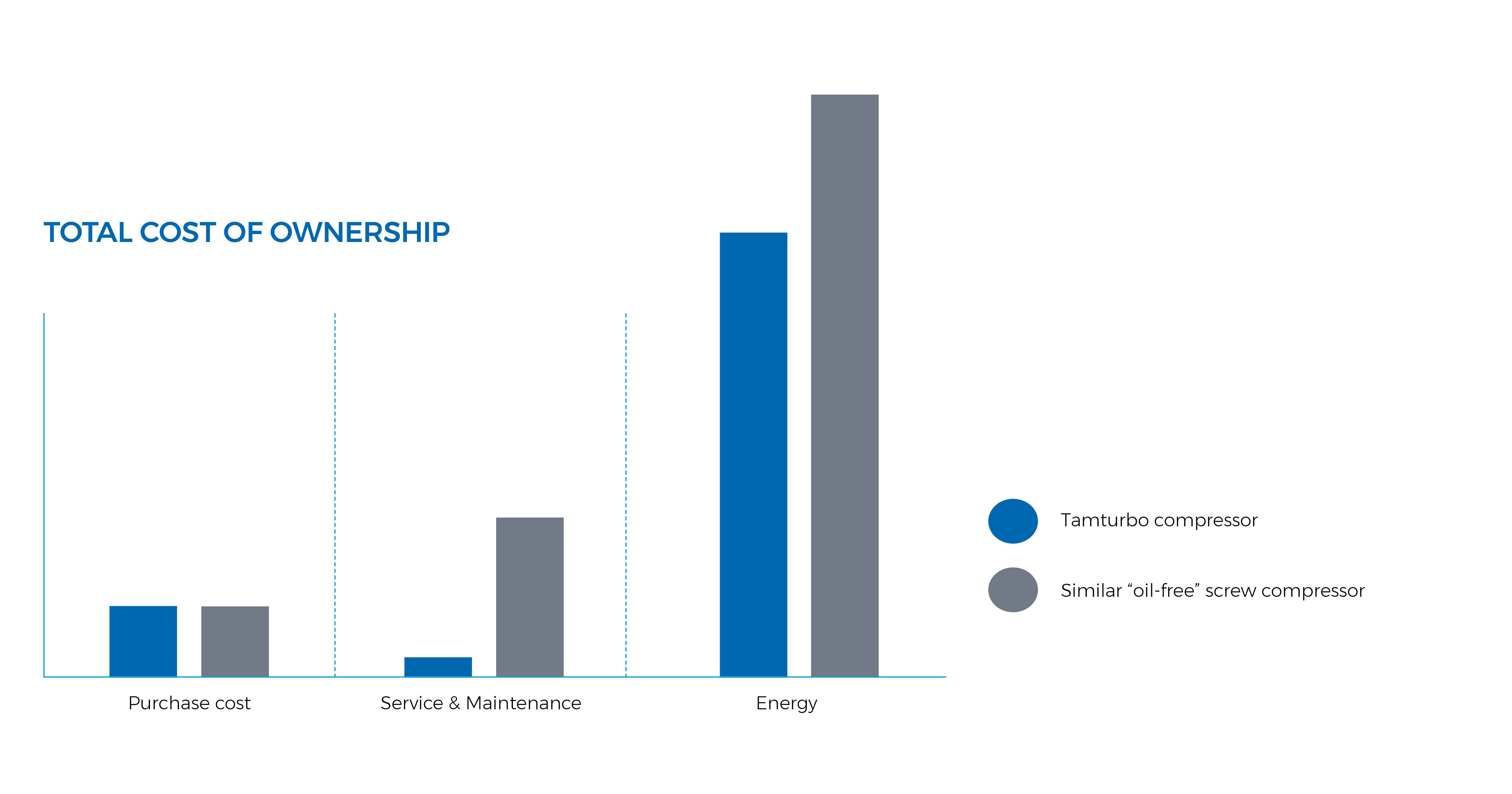

When considering maintenance costs and the total cost of ownership of air compressors, Tamturbo® clearly surpasses traditional technologies. The efficiency of “oil-free” screws deteriorates rapidly as a result from the wear of the screws’ Teflon-coating and other components from day one. This increases the energy consumption by 10–15% and results in costly overhauls every few years. With Tamturbo® Touch-Free™ technology being wear free, the turbo compressor does not need any conventional maintenance. The only consumable part requiring change is the intake air filters. The Touch-Free™ technology is remotely monitored and the compressor informs of the maintenance needs well in advance. Tamturbo® technology is also very energy efficient and the high efficiency remains because there are no wearing parts. With Tamturbo® technology, you can save 10%-15% or more of the energy consumption, compared with older technologies.

In addition to saving a lot of energy, by choosing Touch-Free™ technology you are saving nature. Industrial air compressors use 10% of total industrial electricity and 5% of the world total energy. Therefore air compressors have a clear energy saving potential globally. The biggest savings in nature and energy bills can be achieved with Tamturbo standard heat recovery. More than 90% or the compressor’s energy is captured to warm water. The warm water can be used in industrial processes or facilities. The same energy can be used twice.